Eco Design wood burning stoves - the future of logburners

5 mins

Eco design wood burning stoves - the future of logburners

Eco-design stoves - a selection of our favourites

An eco-design stove is a type of appliance specifically designed with environmental considerations and energy efficiency in mind. These stoves aim to minimize the negative impacts on the environment by reducing emissions, improving fuel efficiency, and utilising sustainable materials. They are often used for heating homes or outdoor areas, and can burn various types of fuel, such as wood, pellets, or biomass.

Key features of eco-design stoves will usally include:

- Lower emissions: These stoves are designed to meet strict emission standards, which means they release fewer pollutants such as particulate matter, carbon monoxide, and nitrogen oxides into the air compared to traditional stoves.

- Higher fuel efficiency: Eco-design stoves are more fuel-efficient, which means they require less fuel to generate the same amount of heat as older, less efficient models. This can lead to lower fuel costs and reduced resource consumption.

- Cleaner burning technology: Many eco-design stoves incorporate advanced combustion technology, such as secondary air supply or catalytic converters, to ensure a cleaner burn and reduce the amount of harmful by-products.

- Improved air quality: By reducing emissions and burning fuel more efficiently, eco-design stoves can help improve indoor and outdoor air quality, contributing to a healthier living environment.

Overall, eco-design stoves are a more environmentally-friendly and sustainable choice for heating, and they can help reduce the carbon footprint of households that rely on them for warmth.

All of the stoves we sell are eco-design and DEFRA approved.

The best Ecodesign stoves are...

View all

It is worth remembering that wood is a renewable resource and much better for our planet than gas or oil (or electricity when it is created by a coal-fuelled power station).

Eco Design is a new standard of stove design that substantially reduces the particulates added to our atmosphere by the burning of wood. This is 80%+ less so than an open fire (open fires and vehicles are the biggest polluters in cities and NOT modern wood stoves read my article about recent press nonsense around wood stoves: are wood stoves bad for the environment?).

From 2022 logburners of all types not approved as “Ecodesign” will not be able to be sold. The law is not retrospective so all stoves sold before this date are still legal.

The latest eco stoves really are more efficient and better for our planet than previous designs.

ALL STOVES WE SELL ARE ECODESIGN APPROVED.

How to choose chimney liner & how much to buy

Installing a stove in a fireplace - what do I need?

FAQs

See all FAQsCosts correct as of April 2023:

Approx. costs if you have a chimney and fireplace ready to use: £750-£1,000 (save £500 by self-installing).

Approx. costs if you have a chimney but need the fireplace "opening up": £1,600-£2,200 (save £1200 by self-installing).

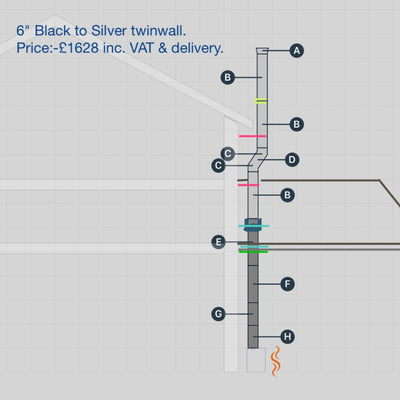

Approx. costs if you do not have a chimney and need a clip-together flue: Shed £475-£700. Bungalow £1500. 2-storey house £2500. Save £1,000-£1400 by self-installing.

Above figures include labour and materials but no appliance.

We, of course, advise you to purchase your stove and materials from Stovefitter's to ensure quality goods are installed (some installers use budget materials to increase margin). If you buy your stove from us (rather than your local small shop or installer) we have a lot more power when approaching manufacturer's with a warranty issue. Why is that? Because we buy many hundreds of stoves a year from these brands.

We do not fit stoves.

But we know a few who do!

Google: Hetas installers

Hetas are the trade body of registered UK installers.

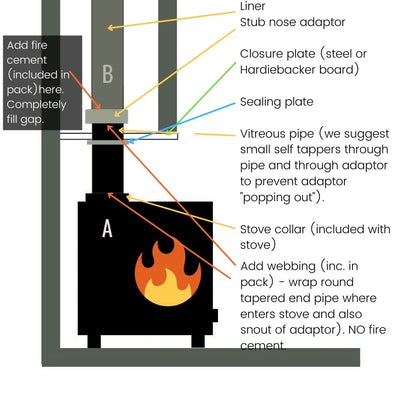

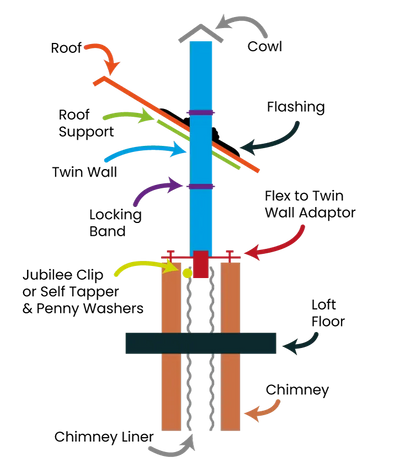

Most installations will require that you slide a chimney liner down your chimney (flexible metal tube 5" or 6" in diameter). Do you have a narrow chimney and want to lessen the risk that a liner might not go down your chimney? Then make sure your chosen stove can use a 5" liner.

Must I line my chimney? Best read this article but most likely the answer is yes. Do I have to fit a chimney liner?

DEFRA-Exempt wood burning stoves with a 5″ collar can usually be fitted to a five inch liner rather than the usual 6″ minimum, making the installer's job much less stressful.

ALL OF THE 5KW STOVES WE SELL CAN BE FITTED TO A 5" CHIMNEY LINER.

I seriously suggest any self installer fits a 5" liner unless they know their chimney is large enough for a 6"!

What is the best chimney liner? Silvacore 904 (we sell it so of course we will say that ;-). What is the best chimney liner?

Useful links

Will your stove require an air vent within the room (some stone walls are very difficult to drill)?

5kW or under and wood burning stoves often do not require an air vent (new builds always require an air vent).

Useful links

What is the maximum output in kW of your "5kW" wood burning stove? The majority of manufacturers just specify the “nominal output” and this figure means very little in real life. The nominal is a figure the manufacturer chooses to sell the stove at - the stove is capable of reaching at least this output with one fuel load. Nominal means "capable of". But it is not the maximum.

Check out the size of the area where the logs will go (firebox size) as this varies enormously. The kW output is completely dependant on the amount of logs burning at any one time - more logs burning equals more heat. If you can fit three logs in stove A and just two logs in stove B then stove A will be capable of throwing out 33% more heat.

DO NOT TRUST MANUFACTURERS’ kW RATINGS as manufacturers specify what output they desire to sell the stove at and testing allows for much “playing with the figures”. This is why you can get very small 5kW stoves (e.g. Aga Little Wenlock) and very large 5kW stoves (e.g. DG Ivar 5 by Dik Geurts which is actually rated 5kW but has a MUCH larger firebox than the Ekol Crystal 5 by Ekol Stoves). A Crystal 5k might get to 5kW and not be capable of any higher whilst a DG Ivar, despite being rated at 5kW, can get to 8kW with a full fuel load.

Note that, over time, one might damage the internal firebricks of a stove by running at a higher load than the manufacturer's suggest. Firebricks are easily replaceable.

Useful links

Will your wood burning stove fit in your recess WITH the required air gaps around it? This is obviously not an issue if your stove will be freestanding.

Air gaps to non-combustible materials (brick, stone etc.) are usually "as close as you like" legally but manufacturers will sometimes specify a recommendation. This recommendation is there to allow heat to escape from the recess into the room - so you get the heat benefit rather than the heat soaking into the building structure and being lost. If no gap to non-combustibles recommended then we suggest 50-100mm air gap left and right of stove, 50mm behind and 100mm above.

Are you in a Smoke Control Area (usually built up areas)?

Choose your stove accordingly.

A stove must be DEFRA-Approved if you wish to burn wood in a smoke control area.

ALL OF THE STOVES WE SELL ARE DEFRA APPROVED FOR SMOKE CONTROL AREAS.

In simple terms if a stove has an efficiency rating of 70% then 30% of the heat from your logs goes up the chimney.

If a stove has an efficiency rating of 90% then only 10% goes up the chimney.

So think of this in terms of how many logs you have to chop/buy.

Example: A Saltfire Peanut 5 by Saltfire Stoves in Dorset has an efficiciency of 80%.

A tall chimney (6m or more) that is lined will be happy with an efficient stove.

Efficiency importance can be said to be overrated and anything between 75% and 85% is fine. Go much higher and performance can actually suffer (smoke in room when opening door to reload, blackening of glass).

Many modern stoves can go on 12mm thick hearths. Others require full, 5″ thick constructional hearths. All of the stoves we sell state whether or not a 12mm hearth is suitable.More about hearths for wood stoves here.

Helpful links

Can you can talk to somebody on the phone should you need to after the wood burning stove has been delivered, especially if you are self installing? Will the staff at “wesellzillionsofstoves.com” be able to assist with any installation issues? What if there are any problems after install?

Do yourself a favour before ordering stoves or materials on the Internet: Go to Trustpilot and type in the company name before you buy. Some companies advertising at the top of search engines are not good news - check for yourself.

When striving to find thebest 5kW wood burning stovesyou will likely be bewildered by the choice. There are many to choose from. The question I get asked most in our shop is “why should I pay <£1,000> for this one when this other one is just <£500>?”. Here is the very simple answer:the cheaper wood stoves are made in Chinaor Eastern Europe whilst the more expensive are made in Western Europe (or sometimes the USA). Here are a few examples where a more expensive stove might excel over a cheaper stove:

- Aesthetics (more time spent on design)

- Hinges (sometimes hidden on more expensive stoves)

- Better quality glass

- Thicker steel (longer life)

- Improved door locking mechanisms

- Longer warranty

- Improved controllabilty of flame due to more resource invested on design of air flow within stove

- Brushed steel fittings instead of cheapy chrome look

Open and close the door on a cheap Chinese stove. Then open and close the door on a DG stove, Arada stoves, Woodford stoves, Hamlet stoves or Saltfire stoves. You’ll understand the difference.

Stove pricing reminds me of wine pricing. A £20 bottle of wine is not double the quality of a £10 bottle of wine (the drinking experience might be improved by 20% as an example). We are talking “the law of diminishing returns here. They are all “fire in a metal box” at the end of the day.

Yes. However, there are specific regulations and restrictions in place to address air pollution concerns, particularly in areas designated as Smoke Control Areas. In these areas, only approved "smokeless" fuels or exempt appliances, such as Defra-approved wood-burning stoves, can be used. These stoves are designed to burn wood more efficiently and produce fewer emissions.

All the stoves we sell are DEFRA approved and Eco-design approved and suitable for all areas of the UK.

Terminology

View all TerminologyA stainless steel tube, slides down a brick/stone chimney to provide a smooth and safe route for smoke.

All of our stoves are approved by DEFRA to burn wood in all UK locations including Smoke Control Areas (towns and cities). Not all stoves are, so be careful if buying elsewhere.

All of our stoves are ECODESIGN approved to be sold in the UK. Not all stoves are, so be careful if buying elsewhere. ECODESIGN is mandatory by law since January 2022.

The base your stove sits on.

If the chimney is the polo mint then the flue is the hole.

More buying guides

View All

How to choose a wood burning stove for your property (includes infographic)

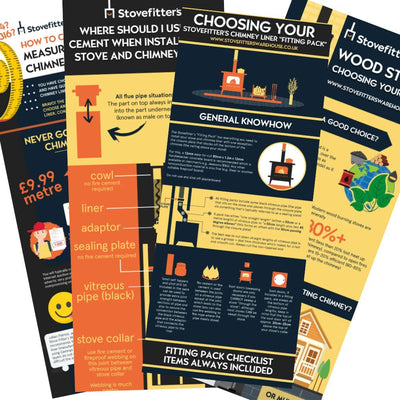

Infographics

What size wood stove do I need? Don't let manufacturers fool you!

Buying Guides

Do I need an air vent for a wood burning stove? If I do not bother?

Buying & DIY

Knowledge Tree: Process of buying and installing a wood burning stove

Buying & DIY

Chinese wood burners – should I buy one or are they all crap?

Buying Guides

What else do I need to buy to install a wood burning stove?

DIY Guides

Infographics for wood burning stove purchase and install

Infographics

Wood burning or multifuel stove? A stove fitter decides.

Buying Guides

A few words from Julian

Buying & DIY

Find my perfect stove

Answer 3 simple questions and we will show you the best Stoves for your space.