Heat shields for wood burning stoves and distance to combustibles

5 mins

Heat shields for wood burning stoves and distance to combustibles

Should I be worried about setting something on fire?

Simple answer - not if you use basic common sense. Fire has been used as a heat source since man entered her first cave. It’s worth following the rules and regulations when it comes to wood burning and multifuel stoves. If you have not used or owned a stove before you might not be aware quite how hot the stove and the flue pipe can get. In normal operation a flue pipe will be at 150 to 250 degrees centigrade but can go a lot higher. If deposits attached to the inside of a flue catch fire then a flue pipe can even glow red (worst case scenario and extremely rare). Building regulations must sensibly cover all eventualities (including a pipe glowing red hot) to protect property and life. The floor underneath a stove or in front of the glass can get much too hot to touch and a suitable hearth is imperative.

A “combustible material” is any material that is not A1 fire-rated or to as high a specification as this (your sofa and that wooden beam are definitely combustible materials!). Plasterboard is officially a combustible material. Materials such as “pink plasterboard” might have increased levels of fire resistance but this does not make them A1 fire-rated (e.g. pink plasterboard might be rated as holding back fire for “x” minutes but this is not the same as A1 fire-rated). A1 fire-rated means that it will not catch fire, full stop, and it will not fall apart in a fire. You are safe with brick, stone and plaster as these are NON-combustible materials.

Stud walls might have wooden battens behind the plasterboard and in this instance normal Building Regulations for combustible rules should be followed (just because the battens cannot be seen does not mean they are safe).

Grey areas? At the end of the day “who is inspecting/signing off the job?” is the real question and it is these people that need to be kept happy. If in doubt err on the side of belt n braces caution..

TOP ADVICE: To make your job very easy just ensure there are no combustible materials anywhere near your stove.

Further down this page look at the rules for the following:

A. the stove

B. the vitreous pipe

C. twin wall (insulated) flue

A, B and C above have three different sets of rules.

Want to build your own chimney breast or fire surround? Google "building fireplace surround Promafour"

Wood burning stoves: distance safety rules

Your stove must be a minimum distance away from combustible materials. This distance will be specified by the stove manufacturer in their installation instructions (contact them if stove not yet purchased). The distances will often be 40cm or more (if you have an inglenook with any combustibles present then it better be a large one). Remember this is to combustible materials. Some stoves can be fitted with manufacturer's-supplied heatshields that reduce distances to combustibles (the Saltfire Scout has a built-in heat-shield and the Hobbit can have rear and side heat shields).

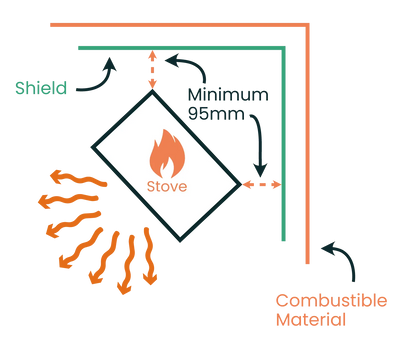

Can you shield the combustibles from the stove and reduce the specified distance by adding a shield to the wall? Yes you can.

If the stove does not exceed a nominal heat output of 7kW then yes.

Some caveats with heat shields

If the following caveats are met then clearance to closest combustibles can be reduced to 95mm between stove and heat shield (see diagrams).

- Stove must be under 7kW nominal

- Shield must be a min 1.5mm thickness galvanised steel (can be painted afterwards to match wall) and affixed with non combustible fittings (e.g. Thunderbolts with copper plumbing pipe cut for spacers)

- Shield shall be open top and bottom to allow flow of air

- The shield must extend at least to the hearth edges and at least 300mm above the top surface of the appliance

- There shall be no protrusions above the shield to prevent air flowing behind the shield

Don't want to bother with a shield?

The 4kW Saltfire Scout has a supplied rear heat-shield and this ensures a very low distance to combustibles at the rear of the stove of just (100mm) 4").

A good example of a full length heat shield is shown in the image.

Hetas's diagram (for comparison with our diagram above) is here.

For a very good but expensive shield see Vlaze at foot of this article.

Note that some stoves can be fitted with a heat shield direct onto the stove (provided by the stove manufacturers). The DG Ivar 5 stove has a distance to combustibles at the rear of 400mm but fit their heat shield directly to the rear of their stove and this is reduced to 150mm. The Ekol Applepie also has an optional purpose built enclosure. The Saltfire Scout has a heat shielduilt into the stove - so no extra cost for the consumer.

Stoves and non-combustible materials: read the manual

What appears to be a complete mystery when it comes to Building regs, most installation guides and stove manuals is minimum VERTICAL distances to combustible materials (usually a wooden beam or lintel).

BS1251 says

3.1.4 – Wooden Mantels

“Where a fireplace consists of a marble, stone or ceramic back panel and hearth together with a wooden mantelpiece. There shall be a clearance to combustible material of 300 mm above the fire opening and 150 mm either side of the fire opening to the start of the wooden mantel. Extra clearance may be needed when the fireplace is constructed for certain types of appliance”

This advice therefore should be followed as ‘good practice’ in lieu of no other directive.

A selection of stoves that can have heat shields

Vitreous flue pipe: distance safety rules

View all

Steel flue pipe (often called vitreous pipe) is the pipe that comes out of the top of the top or rear of the majority of stoves. Flue pipes GET EXTREMELY HOT and should be located as to avoid igniting combustible materials. See clause 2.15 and diagram 19 of ADJ (Document J of the Building Regulations).

The key rule for all flue pipe is that:

Any combustible material must be three times “X” away from the flue pipe where X = the diameter of the flue pipe.

This means that your 5″ flue pipe should be 15″ away from combustibles and your 6″ flue pipe should be 18″ away from combustibles in any direction.

This distance can be halved if you shield the combustible material. The shield must, of course, be non-combustible (do not use plasterboard as it is not A1 fire-rated and may gradually crumble).

There must also be an air gap between the shield and the combustible material of a minimum of 12mm (other wise the combustible material soon ends up the same temp as the shield).

FOR BEST PRACTICE USE 25MM AIR GAP.

The air gap is very important – just sticking the shield to the combustible material does not work as the heat just passes through the shield. Air is an excellent insulator.

Vitreous and non-combustible materials: close as you like.

Shielding wood beam from stove or steel flue pipe (vitreous pipe)

As already mentioned it is possible to shield a combustible material e.g.a wooden beam from the heat from a heat source.

As can be seen from the regulations outlined above shielding can reduce the minimum allowed distance between pipe and material to 1.5 X diameter rather than 3 X diameter (5″ pipe when shielded can be 7.5″ away and 6″ pipe can be 9″ away). As a fitter I have one problem with this… I correct myself… the customer usually has one problem with this. As can be seen from the diagram (fig.1) below, in order to be effective the shield always has to drop below the wooden beam. This means the shield can be seen from the room, especially when sitting on the sofa. The amount that is usually showing is 2 to 5″. I usually have to inform customers that they have no choice in the matter.

In the the second diagram (fig.2) the long orange arrow (distance from flue to wood) must be a minimum 15″ (5″ diameter flue) or 18″ (6″ diameter flue). The short red arrows show an area where the gap should be half of this (7.5″ or 9″). The gap between shield and combustible material must be 12mm minimum (BEST PRACTICE 25MM).

In the example below, if the steel flue is 5″, then the two long orange arrows should be 15″ or more whilst the short red arrows should be 7.5″ or more.

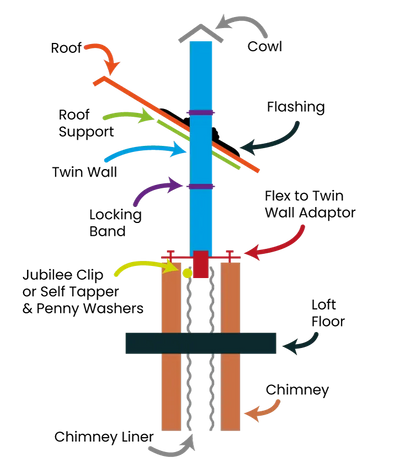

Twin wall clip-together flue: safety rules

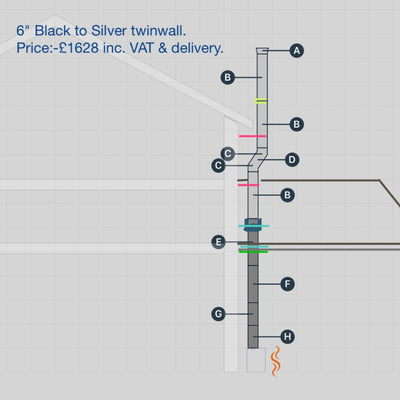

View allTwin wall flue pipe has a diameter of approx. 2″ more than steel stove pipe due to it being insulated (so a 6″ diameter vitreous would be an 8″ exterior twin wall). It is usually used to pass through ceilings and lofts or run outside of buildings (it is often stainless steel but is also available in black).

Note that when you purchase twin wall pipe it is the interior size you specify (so our 6" twin wall is 6" inside).

Twin Wall flue, because it is insulated, only has to be a minimum Xcm from combustibles. “X” is usually 5cm, 6cm or 7cm depending on supplier so please check (it might be 5cm in open air and 8cm if “boxed in”). Duraflue Easy Fit should be 7cm from combustibles if boxed in but can be 5cm if in open air. Twin Wall Flue is used to build complete chimney systems where no chimney is present but is also used in place of the usual vitreous steel stove pipe in areas where a combustible material is close by and is often used in place of steel in order to protect wooden beams or surrounds.

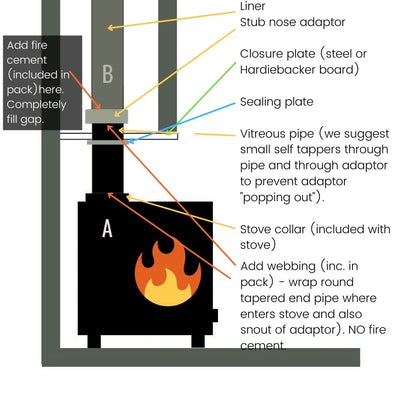

In order to bypass a wooden beam one requires, from the bottom up: short length steel vitreous pipe (usually 25cm length), vitreous to twin wall adaptor, length of twin wall (usually a metre or a metre and a half), twin wall to flue liner adaptor, chimney liner. One can choose to go straight to the stove with the twin wall and one would then just omit the short length of vitreous pipe.

Note that joints in twin wall are, according to regs, supposed to be able to be inspected and a suitable inspection hatch fitted (30cm x 30cm minimum). One way of achieving this is to make your closure register plate removable in some form (even if removing it is a pain at least you have complied).

Twin wall and non-combustible materials: close as you like.

Why not make your own heat shields?

Why not make your own heat shields?

A company called Vlaze launched “aesthetically lovely” heat shields (see pic). VLAZE wall mounted heat shields are designed to be hung behind a wood burning stove creating a focal point that not only enhances the fireplace but allows the stove to be placed close to the wall behind. When installed the shield reduces the stoves distance to a combustible material by half and in the case of Charnwood appliances down to just 100mm.

Vlaze panels are however very heavy and expensive (£300-£500). One might agree that they are somewhat over-engineered. If you are prepared to put the funds and effort into Vlaze – they are rather lovely.

You can make your own heatshield from thin steel or 7mm Hardiebacker board (Google it). Offset from the wall using metal tubing as spacers (e.g. copper pipe or even a stack of nuts or washers will do). Then paint the shield same colour as the wall with standard water based emulsion (or some spray it with black stove-spray or bbq paint). Simples.

"The stove I own is the DG Ivar 5, the best logburner on the market today as far as I am concerned"

Julian Patrick, site owner and author of The Stovefitter's Manual.

Other articles that may be useful

More articles

Wood burning stoves installation advice and buyer's guides. Welcome to The Stovefitter's Manual.

Buying & DIY

Quick links: Legal stuff. Installer list. Building regs etc.

Rules & regulations

Building Regulations for wood burning stoves – who are Building Control and who polices?

DIY Guides

Building regulations for the fireplace

DIY Guides

Heat shields for wood burning stoves and distance to combustibles

DIY Guides

Hearth sizes and regulations for a wood burning stove

DIY Guides

Infographics for wood burning stove purchase and install

Infographics

Can I fit my own wood burning stove?

DIY Guides

Can I have a wood burning stove if I have no chimney?

Buying Guides

Can I install a wood burning stove in a conservatory

Buying Guides

FAQs

See all FAQ'sCosts correct as of April 2023:

Approx. costs if you have a chimney and fireplace ready to use: £750-£1,000 (save £500 by self-installing).

Approx. costs if you have a chimney but need the fireplace "opening up": £1,600-£2,200 (save £1200 by self-installing).

Approx. costs if you do not have a chimney and need a clip-together flue: Shed £475-£700. Bungalow £1500. 2-storey house £2500. Save £1,000-£1400 by self-installing.

Above figures include labour and materials but no appliance.

We, of course, advise you to purchase your stove and materials from Stovefitter's to ensure quality goods are installed (some installers use budget materials to increase margin). If you buy your stove from us (rather than your local small shop or installer) we have a lot more power when approaching manufacturer's with a warranty issue. Why is that? Because we buy many hundreds of stoves a year from these brands.

We do not fit stoves.

But we know a few who do!

Google: Hetas installers

Hetas are the trade body of registered UK installers.

Helpful links

Most installations will require that you slide a chimney liner down your chimney (flexible metal tube 5" or 6" in diameter). Do you have a narrow chimney and want to lessen the risk that a liner might not go down your chimney? Then make sure your chosen stove can use a 5" liner.

Must I line my chimney? Best read this article but most likely the answer is yes. Do I have to fit a chimney liner?

DEFRA-Exempt wood burning stoves with a 5″ collar can usually be fitted to a five inch liner rather than the usual 6″ minimum, making the installer's job much less stressful.

ALL OF THE 5KW STOVES WE SELL CAN BE FITTED TO A 5" CHIMNEY LINER.

I seriously suggest any self installer fits a 5" liner unless they know their chimney is large enough for a 6"!

What is the best chimney liner? Silvacore 904 (we sell it so of course we will say that ;-). What is the best chimney liner?

Useful links

Will your stove require an air vent within the room (some stone walls are very difficult to drill)?

Because a fire consumes air from the room (sends it up the chimney) new air needs to enter the room to replace it. Otherwise a vacuum will be created and the stove will die down or underperform.

5kW or under and wood burning stoves often do not require an air vent as a room has enough natural leakage. More airtight new-builds always require an air vent.

It is easy to test if a stove is getting enough air: open a window a little and if the fire"springs to life" or "performs better" then an air vent is likely required. Rarely is a room so airtight that a 5kW stove requires a vent.

Useful links

What is the maximum output in kW of your "5kW" wood burning stove? The majority of manufacturers just specify the “nominal output” and this figure means very little in real life. The nominal is a figure the manufacturer chooses to sell the stove at - the stove is capable of reaching at least this output with one fuel load. Nominal means "capable of". But it is not the maximum.

Check out the size of the area where the logs will go (firebox size) as this varies enormously. The kW output is completely dependant on the amount of logs burning at any one time - more logs burning equals more heat. If you can fit three logs in stove A and just two logs in stove B then stove A will be capable of throwing out 33% more heat.

DO NOT TRUST MANUFACTURERS’ kW RATINGS as manufacturers specify what output they desire to sell the stove at and testing allows for much “playing with the figures”. This is why you can get very small 5kW stoves (e.g. Aga Little Wenlock) and very large 5kW stoves (e.g. DG Ivar 5 by Dik Geurts which is actually rated 5kW but has a MUCH larger firebox than the Ekol Crystal 5 by Ekol Stoves). A Crystal 5k might get to 5kW and not be capable of any higher whilst a DG Ivar, despite being rated at 5kW, can get to 8kW with a full fuel load.

Note that, over time, one might damage the internal firebricks of a stove by running at a higher load than the manufacturer's suggest. Firebricks are easily replaceable.

Useful links

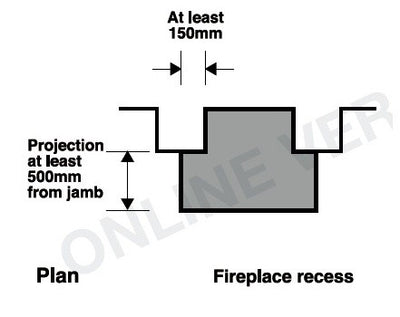

Will your wood burning stove fit in your recess WITH the required air gaps around it? This is obviously not an issue if your stove will be freestanding.

Air gaps to non-combustible materials (brick, stone etc.) are usually "as close as you like" legally but manufacturers will sometimes specify a recommendation. This recommendation is there to allow heat to escape from the recess into the room - so you get the heat benefit rather than the heat soaking into the building structure and being lost. If no gap to non-combustibles recommended then we suggest 50-100mm air gap left and right of stove, 50mm behind and 100mm above.

Distance to COMBUSTIBLE materials (usually wood) please follow the link below.

Are you in a Smoke Control Area (usually built up areas)?

Choose your stove accordingly.

A stove must be DEFRA-Approved if you wish to burn wood in a smoke control area.

ALL OF THE STOVES WE SELL ARE DEFRA APPROVED FOR SMOKE CONTROL AREAS.

In simple terms if a stove has an efficiency rating of 70% then 30% of the heat from your logs goes up the chimney.

If a stove has an efficiency rating of 90% then only 10% goes up the chimney.

So think of this in terms of how many logs you have to chop/buy.

Example: A Saltfire Peanut 5 by Saltfire Stoves in Dorset has an efficiciency of 80%.

A tall chimney (6m or more) that is lined will be happy with an efficient stove.

Efficiency importance can be said to be overrated and anything between 75% and 85% is fine. Go much higher and performance can actually suffer (smoke in room when opening door to reload, blackening of glass).

Many modern stoves can go on 12mm thick hearths. Others require full, 5″ thick constructional hearths. All of the stoves we sell state whether or not a 12mm hearth is suitable.

Small stove in a shed, garage, gazebo etc? Choose a stove that go on a 12mm hearth. Then go to a builders merchants' outdoor yard (or slate/granite supplier but that will be expensive) and find a nice slab (best 20mm thick - 30mm thick) of 84cmx84cm (building regs says this is minimum for a freestanding stove not in a fireplace).

84cm x84cm seems too big? If your install is in a non-habitable location and you are not getting it signed off - do what you wish. We strongly suggest 30cm of hearth in front of the stove to catch any stray embers when you open the stove door.

Helpful links

Can you can talk to somebody on the phone should you need to after the wood burning stove has been delivered, especially if you are self installing? Will the staff at “wesellzillionsofstoves.com” be able to assist with any installation issues? What if there are any problems after install?

Do yourself a favour before ordering stoves or materials on the Internet: Go to Trustpilot and type in the company name before you buy. Some companies advertising at the top of search engines are not good news - check for yourself.

When striving to find thebest 5kW wood burning stovesyou will likely be bewildered by the choice. There are many to choose from. The question I get asked most in our shop is “why should I pay <£1,000> for this one when this other one is just <£500>?”. Here is the very simple answer:the cheaper wood stoves are made in Chinaor Eastern Europe whilst the more expensive are made in Western Europe (or sometimes the USA). Here are a few examples where a more expensive stove might excel over a cheaper stove:

- Aesthetics (more time spent on design)

- Hinges (sometimes hidden on more expensive stoves)

- Better quality glass

- Thicker steel (longer life)

- Improved door locking mechanisms

- Longer warranty

- Improved controllabilty of flame due to more resource invested on design of air flow within stove

- Brushed steel fittings instead of cheapy chrome look

Open and close the door on a cheap Chinese stove. Then open and close the door on a DG stove, Arada stoves, Woodford stoves, Hamlet stoves or Saltfire stoves. You’ll understand the difference.

Stove pricing reminds me of wine pricing. A £20 bottle of wine is not double the quality of a £10 bottle of wine (the drinking experience might be improved by 20% as an example). We are talking “the law of diminishing returns here. They are all “fire in a metal box” at the end of the day.

Yes. However, there are specific regulations and restrictions in place to address air pollution concerns, particularly in areas designated as Smoke Control Areas. In these areas, only approved "smokeless" fuels or exempt appliances, such as Defra-approved wood-burning stoves, can be used. These stoves are designed to burn wood more efficiently and produce fewer emissions.

All the stoves we sell are DEFRA approved and Eco-design approved and suitable for all areas of the UK.

Terminology

View all TerminologyA stainless steel tube, slides down a brick/stone chimney to provide a smooth and safe route for smoke.

All of our stoves are approved by DEFRA to burn wood in all UK locations including Smoke Control Areas (towns and cities). Not all stoves are, so be careful if buying elsewhere.

All of our stoves are ECODESIGN approved to be sold in the UK. Not all stoves are, so be careful if buying elsewhere. ECODESIGN is mandatory by law since January 2022.

The base your stove sits on.

If the chimney is the polo mint then the flue is the hole.

Buying guides

View All

How to choose a wood burning stove for your property (includes infographic)

Infographics

What size wood stove do I need? Don't let manufacturers fool you!

Buying Guides

Do I need an air vent for a wood burning stove? If I do not bother?

Buying & DIY

Knowledge Tree: Process of buying and installing a wood burning stove

Buying & DIY

Chinese wood burners – should I buy one or are they all crap?

Buying Guides

What else do I need to buy to install a wood burning stove?

DIY Guides

Infographics for wood burning stove purchase and install

Infographics

Wood burning or multifuel stove? A stove fitter decides.

Buying Guides

A few words from Julian

Buying & DIY

Find my perfect stove

Answer 3 simple questions and we will show you the best Stoves for your space.